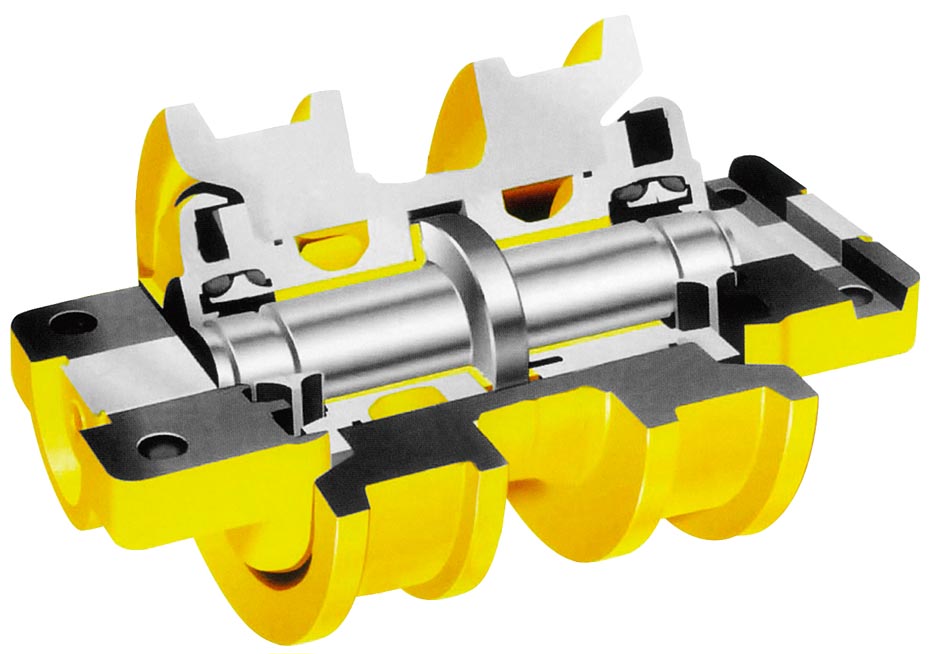

Qaab dhismeedka rullalulatada hoose waxaa inta badan loo kala qaybiyaa jirka giraangiraha, shafka taayirrada ee taageera, shafka shafka, saliida sabaynaysa, iyo daboolka dhamaadka.

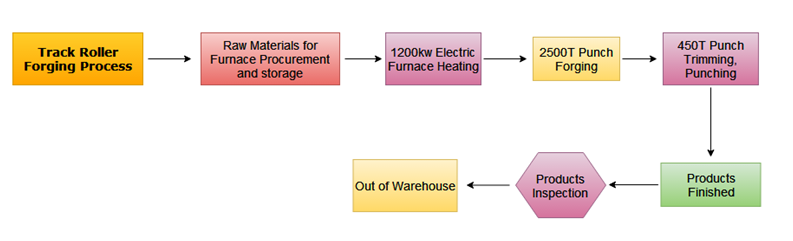

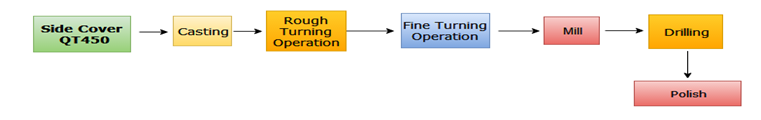

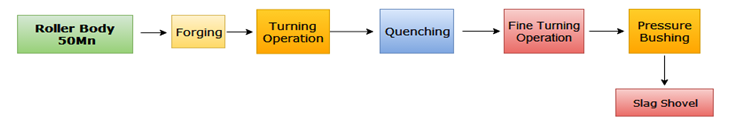

Si loo sameeyo rullaluistemadka raadadka tayada sare leh waxay inta badan ku xiran tahay waxqabadka birta.Walaxda rollerku guud ahaan waa 50Mn, 40Mn2, (MN: oo la mid ah curiyaha manganese).Habka wax-soo-saarka ayaa loo qaybiyaa shubid ama been-abuur, mashiin, ka dibna daaweynta kulaylka.Ka dib marka dusha sare ee giraangiraha la demiyo Adaggu wuxuu gaaraa HRC55 ~ 58 si loo kordhiyo caabbinta xirashada ee dusha giraangiraha.

Shuruudaha saxsanaanta makiinada ee rollers-ka taageeraya ayaa aad u sarreeya.Guud ahaan, qalabka mashiinka CNC ayaa looga baahan yahay mashiinka si loo buuxiyo shuruudaha.

Waxaa jira walxo badan oo 40Mn2 ah, oo engegnaantuna waxay gaartaa ilaa HRC52.

Maxaa loo baahan yahay in fiiro gaar ah loo yeesho inta lagu jiro hawlgalka roller-ka?

1. Inta lagu jiro shaqada laamiga, masaafada loo socdaalay waa in aanay noqon mid aad u dheer, xawaaruhuna waa in aanu aad u dheerayn;giraangiraha taageerada ayaa dhalin doona heerkul sare inta lagu jiro wadista degdega ah ee muddada dheer, saliidda saliidayntu waxay soo daadan doontaa sababtoo ah qasin.Waxyeello u geysato taayirrada taageeraya.Marka la ogaado in rullaluistu ay dhaawacday, waa in lagu beddelaa wakhtiga, haddii kale rullaluistuyada ku xiga sidoo kale waa la dedejin doonaa xidhashada xoogga xad-dhaafka ah.Marka la beddelayo rollers-yada taageerada, xaaladda xirashada waa in la tixgeliyaa.Haddii heerka xirashada uu yar yahay, keligiis waa la bedeli karaa, haddii kale dhammaan waa in la beddelaa, si aan loo dardargelin xirashada rullaluistemadka beddelka cusub.

2. Maaddaama shayga ku yaal laamigu uu yahay mid aad u culus, bartamaha culeyska mashiinka oo dhan ayaa leexanaysa, sidaas darteed rolalka dambe ee paverku waxay wataan xoogga ugu weyn inta lagu jiro habka shaqada, taas oo sahlan in la dhaawaco, oo laamigu wuxuu noqon karaa waxyeello haddii ay dhaawacdo.Marka la socdo waxaa kor iyo hoos u kacaya sharacadu, taas oo keeni doonta in wadada laamiga ah ay noqoto mid hirgal ah, taasoo si toos ah u saamaysa habsami u socodka wadada.

Dhibaatooyinka u nugul rollers-ka:

1. Duubista jirka.Sababta xaaladdan ayaa ah in birta loo isticmaalo aan u qalmin ama adkaanta walxaha inta lagu jiro daaweynta kulaylku waa yar yahay, iyo caabbinta xirashada ayaa maqan.

2. Saliida oo daadato.Shaadhka shaagaga ayaa si joogto ah ugu wareegaya dhinaca shafka, waxaana loo baahan yahay in jidhka taayirrada la subiyo si uu u siman yahay, laakiin haddii giraanta wax lagu xidhaa aanay fiicnayn, way fududahay in ay keento daadinta saliidda, si ay usha iyo shafka gacanta u galaan. way fududahay in la xidho marka aanay simanayn.Alaabta la sameeyay lama joojin karo isticmaalka.

Waxaa jira dhowr sababood oo saliidda daadsan?

1. Saliid sabaynaysa oo aan u qalmin

2. Wareegga gacanta alaabta kuma filna

3. Dhallaalka fulcrum oo aan ku filnayn

4. Saliida Gear ma aha mid heerkeedu gaarsiisan yahay

5. Dhibaatada mishiinada dulqaadka cabbirka, iwm. waxay sababi doontaa daadinta saliidda rollers-ka

JINJIA MACHINERY waa ganacsi hormuud u ah mashiinada injineernimada oo leh qaybo badan oo ka mid ah qaybaha hoose ee rullaluistuyada hoose, rullaluistuyada sare, sprocket, silsiladaha shaqo la'aanta iyo raadadka iyo kabaha raadraaca iyo sumcad wanaagsan ilaa 1990.

Waqtiga boostada: Oct-23-2021